Bogie Hearth Furnace

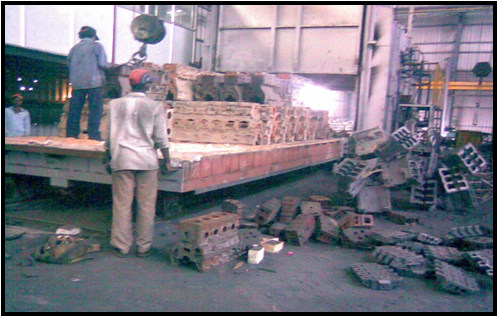

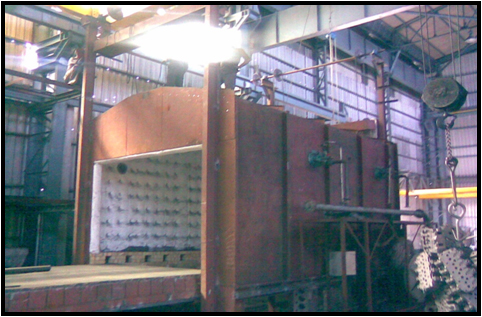

Bogie Hearth Furnace also known as Car bottom furnace is used for Annealing, Normalizing, Hardening, Stress Relieving, Solution Annealing, Tempering, etc. of various grades of Steels in the form of forgings, castings, fabricated components etc. The photograph shows 15-ton capacity Double-ended Bogie Hearth Furnace. In order to save energy and time two bogies are provided, one of them is inside the furnace while other one gets unloaded and loaded for next cycle This is with duel fuel i.e. LPG / HSD Firing System with PLC and SCADA control. The Bogie and door movement is electro-mechanical.

We can build Bogie Hearth Furnace for any charge weights. Operating temperatures may vary from low temperature application with gas circulation to temperature above 1200°C. Furnace can be offered with single bogie or double bogie, with motorised rack and pinion drive system, motorised or pneumatic door operation, effective sealing arrangement etc. The heating could be gas or liquid fuel fired including high velocity burners and also electrically heated. We can also offer radiant tube fuel firing for special applications [ as in case of heat treating aluminium products] and charging machines for handling bogies. We offer oil fired bogie hearth type tempering furnaces for the tempering of hardened alloy steel bars, coils and castings.

Salient features